INDUCTION BOLT HEATER

INDUCTION SHRINK FITTING

INDUCTION BRAZING

Induction Heating Solutions for Power Generation and Petrochemical Industries

Induction Heating Solutions for Power Generation and Petrochemical Industries

Our company manufactures high-quality induction equipment tailored to the needs of plant services that perform maintenance work. Our products have a wide range of applications, from tightening and loosening turbine bolts to nut heat ing, shrink-fitting, and brazing. Our induction system is suitable for heating all kinds of electrically conductive materials like copper, aluminum, steel, stainless, brass, and titanium. We manufacture, sell, rent, and service induction heating equipment necessary for performing outage maintenance of turbines, valves, and compressors in power plants, as well as large refineries. Highly trusted for exceptional quality and timely delivery, we strive to reduce the cost and time for our clients’ maintenance work while ensuring quality.

Induction Heating Solutions for Power Generation and Petrochemical Industries

Induction Heating Solutions for Power Generation and Petrochemical Industries

Our company manufactures high-quality induction equipment tailored to the needs of plant services that perform maintenance work. Our products have a wide range of applications, from tightening and loosening turbine bolts to nut heat ing, shrink-fitting, and brazing. Our induction system is suitable for heating all kinds of electrically conductive materials like copper, aluminum, steel, stainless, brass, and titanium. We manufacture, sell, rent, and service induction heating equipment necessary for performing outage maintenance of turbines, valves, and compressors in power plants, as well as large refineries. Highly trusted for exceptional quality and timely delivery, we strive to reduce the cost and time for our clients’ maintenance work while ensuring quality.

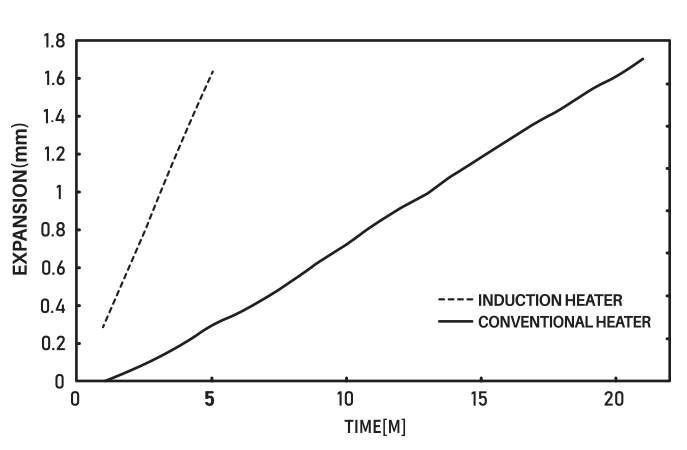

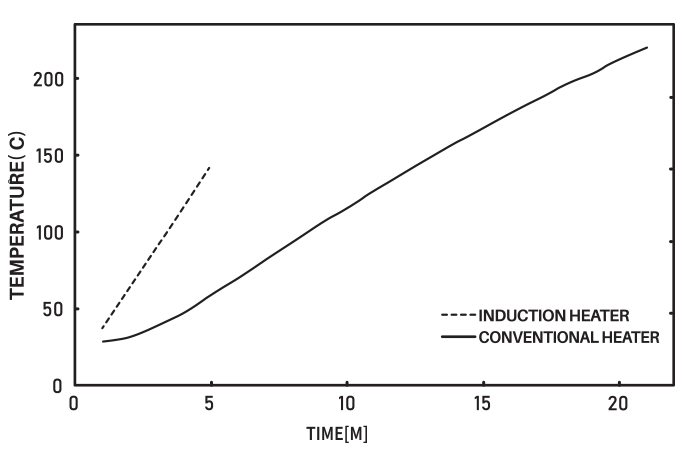

Induction Bolt Heater

Conventional Resistance Heater

REFERENCES

PATENT

Patent#10-1964920

(2019.03.27)

COOLING DEVICE FOR

INDUCTION HEATING SYSTEM

Patent# 10-1996301

(2019.06.28)

WATER COOLING TYPE FLEXIBLE

COAXIAL CABLE FOR INDUCTION

HEATING SYSTEM